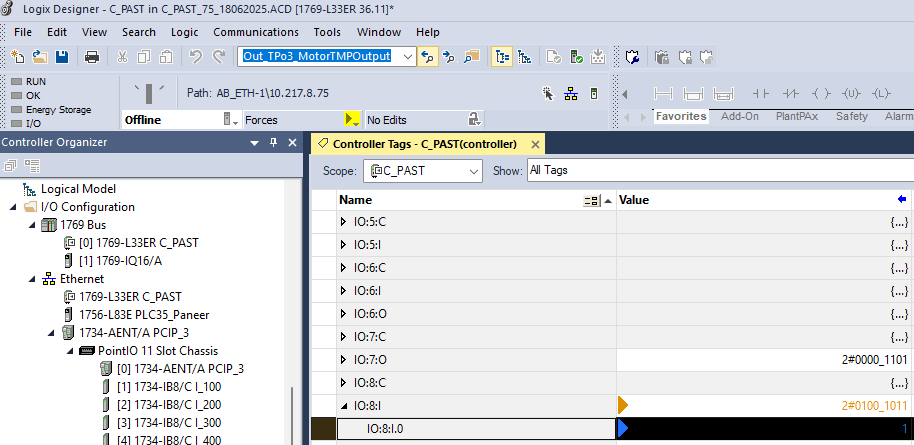

PLC device failures in systems like chemical plating or mining conveyors can halt production. Forcing I/O in Studio 5000 for PLC troubleshooting lets you test inputs and outputs to diagnose hardware issues quickly. This guide shows how to use Studio 5000 with Allen-Bradley PLCs like CompactLogix or ControlLogix to resolve problems efficiently.

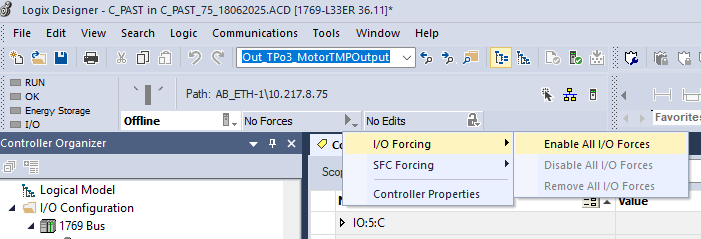

Forcing I/O overrides input or output states to simulate conditions, helping isolate faulty sensors, actuators, or wiring. It’s ideal for troubleshooting ControlLogix or CompactLogix systems without altering logic, ensuring safe diagnostics in industrial environments.

Follow Rockwell’s safety guidelines to prevent equipment damage.

Forcing I/O in Studio 5000 simplifies troubleshooting for reliable automation. Ready to fix your PLC? Explore more helpful troubleshooting tips at Studio 5000 Logix Designer Online Help here. Let Automation Ready Panels design and program your next PLC control system today! Contact Us

In our last project, schedule and quality were very good.�? Also, the coordination and help during installation was good.

Metro Sewer District

David, Senior Electrical Engineer

As far as the internal wiring of the enclosures, I did not find a single wiring error.�? That is very impressive considering the number of enclosures we ordered. I want to thank everyone for the great work.

Brewing Company

Steve, Project Manager

I receieved excellent customer support, and quickly. Thank you so much!

Oil and Gas

John Herman, Controls Engineer

We needed a simple, easy-to-install chemical addition and mixing control system. Started up without an issue. Our operators seem pleased with the outcome!

Chemical Processing Plant

Jacob, Production Manager

We ll Get Back To You Quickly!