Our PLC Applications and Uses

Delivered in 7 days

- Our Value

Programmable Logic Controllers Will Benefit Your PLC Applications

- Our Value

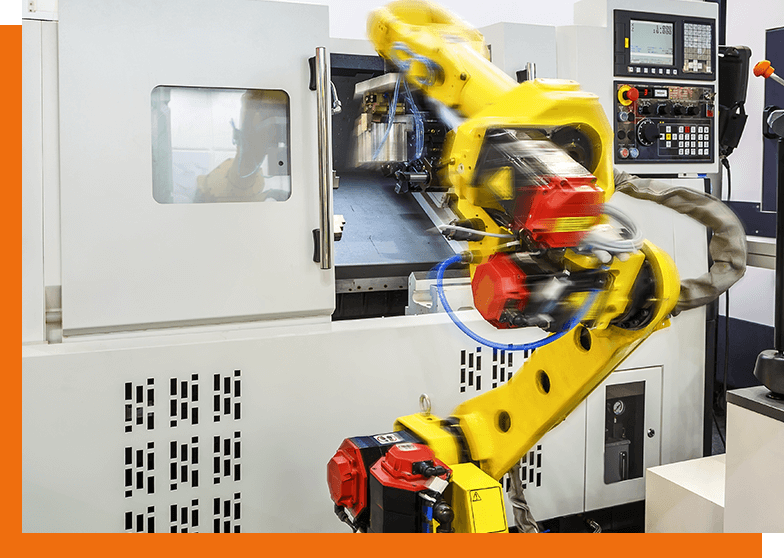

Other Great PLC Applications for our Control Panels

PLC Control Panels can be applied to a number of industrial purposes. With flexible network connectivity and a standard ease of use, you’ll achieve the right amount of control capability for any operation and quickly maximize efficiency.

- Packaging Operations

- Material Handling Lines

- Converting, Print, Web Production

- Process Skid Systems

- Manufacturing and Assembly Lines

- Solar Energy

View this brochure to learn more about PLC control panels and a range of accompanying products to aid in your industrial operations.

- Our Value

PLC Control Panel Application for Packing Operations

Intermittent Vertical Form Fill Seal (VFFS) machines package everyday products. These machines must accurately detect where to cut and seal each package at incredibly high speeds as they’re filled with materials. Typically, some sort of marker such as a logo will indicate the dimensions of the packaging to notify when the machine will cut and seal each individual package.

PLC Control Panels are fundamental for this process, as they control how the system operates and make management more efficient. The touch probe is a motion control feature to precisely detect each marker and notify the web puller when to stop. Because these PLCs function on separate hardware, the motion is separate from the scan, which means you can achieve a higher production level without sacrificing quality

- Our Value

PLC Control Panel Application for Material Handling

Material handling allows packages to be distributed from one location to another easily and quickly, such as organizing boxes for different distribution centers or moving one product from one main conveyor line to a sub-conveyor.

The PLC control panel will be the hub of your system, with other software and systems reporting back to the controller. The PLC will quickly calculate when each package is in the correct position on the main conveyor belt to be pushed to another line and will then signal the actuator to push the package to the new conveyor belt. Network diagnostics are available to pair with the PLC control panel which can help with lowering start-up times, maintenance, and downtime, thus increasing productivity.

- Our Value

PLC Control Panel Application for Remote Water Systems

PLC Control panels can also be applied to remote systems that can be managed through data connection. This allows the water system to operate even if the water tank and pump are miles apart and can be managed without an operator physically being on-site. These PLC control panels offer the ultimate level of convenience.

This system works by one panel detecting the water level and another powering the pump on and off. As it uses cellular data, it requires minimal installation costs as well as lower operation costs since it uses SMS messaging. Status updates will be sent to the operator’s cell phone. This allows the operation to continue running smoothly and autonomously. The system diagnostics and status is also shown on LCD displays that are attached to each PLC control panel.

- Our Value

Maximize Efficiency and Productivity Today!

- Ready for reliable PLC panels?

- Review

Customer Reviews

In our last project, schedule and quality were very good.�? Also, the coordination and help during installation was good.

Metro Sewer District

David, Senior Electrical Engineer

As far as the internal wiring of the enclosures, I did not find a single wiring error.�? That is very impressive considering the number of enclosures we ordered. I want to thank everyone for the great work.

Brewing Company

Steve, Project Manager

Excellent Customer Support

I receieved excellent customer support, and quickly. Thank you so much!

Oil and Gas

John Herman, Controls Engineer

Great Product.

Chemical Processing Plant

Jacob, Production Manager

- Contact US

Ask Any Question

We ll Get Back To You Quickly!