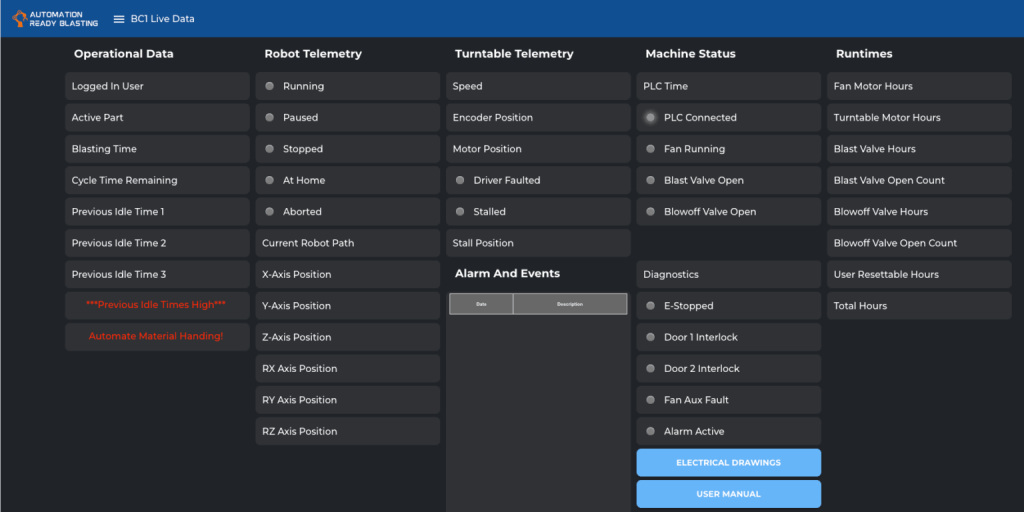

tions, enabling real-time monitoring, alerts, and analytics. It integrates with PLCs like CompactLogix for seamless factory-wide visibility.

An MQTT dashboard delivers real-time value, empowering operations, maintenance, and stakeholders for smarter factories. Ready to implement? Explore our PLC+ Care product page for a deeper look. Let Automation Ready Panels create actionable insights with our live MQTT Dashboard for many different types of machinery or process control systems! Contact Us

In our last project, schedule and quality were very good.�? Also, the coordination and help during installation was good.

Metro Sewer District

David, Senior Electrical Engineer

As far as the internal wiring of the enclosures, I did not find a single wiring error.�? That is very impressive considering the number of enclosures we ordered. I want to thank everyone for the great work.

Brewing Company

Steve, Project Manager

I receieved excellent customer support, and quickly. Thank you so much!

Oil and Gas

John Herman, Controls Engineer

We needed a simple, easy-to-install chemical addition and mixing control system. Started up without an issue. Our operators seem pleased with the outcome!

Chemical Processing Plant

Jacob, Production Manager

We ll Get Back To You Quickly!